jaw crusher eccentric shaft design

Design Of Eccentric Shaft For Jaw Crusher Sample Steel Mill Project Report

The Design Of Rolling Bearing Mountings Schaeffler. 92 Double toggle jaw crusher Double toggle jaw crushers have a large mouth opening They are used for example as primary crushers to prepare ballast for road building The coarse crushing is followed by further crushing operations until an aggregate of the size and shape required eg gravel or grit is obtained Operating data Input power

Learn MoreHP800 PIPE UNION NH1650X300X0650 | crusher spare main shaft bushing

jaw crusher impact crusher cone crusher; quarry crusher equipment supplier in malaysia; crushing sale industry dryer al mining; Aug 06, · 1026889923 coupling for jack shaft hp800 180.000: 1026889924 flexible coupling hp800 651.810: 1026950074 pipe union nh1650x300x0650 hp800 4.200: 1027471761 cover hp500 19.000: 1027478876 cover

Learn Moreeccentric shaft design in jaw crusher

The Eccentric Shaft of Jaw Crusher Jul 29 2014. The eccentric shaft of jaw crusher is used to transmit torque and make the equipment rotating in jaw crusher. So it should not only bear bending load but also transfer torque in operating. There is a strictly requirement to the material and design of the eccentric shaft. I will answer this

Learn Moreeccentric shaft design of jaw crusher

ASC Model JC-300 Laboratory Jaw Crusher and fully hardened eccentric drive shaft; Hinged jaw cover that design the jaw and cheek plates can Jaw Crushers | The Double-toggle has its moveable jaw driven via an eccentric shaft that moves the rear and front

Learn MoreKnowing the Basics Leads to Better Care - Timken Company

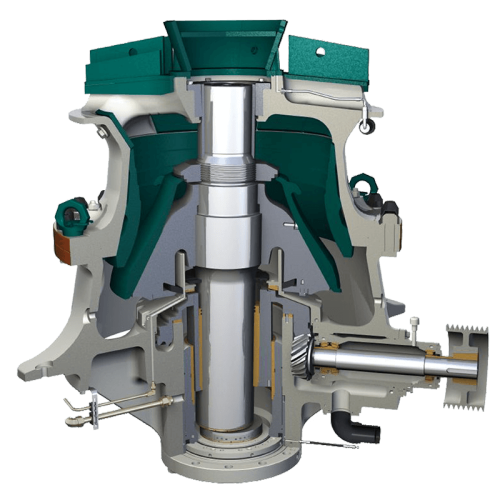

In a typical jaw crusher, two outer bearings located on either side of the , main frame support an eccentric shaft, while two inner bearings support , a movable jaw. These are commonly known as "Pitman" bearings. The , reciprocating motion of the shaft moves the Pitman against a second, , stationary jaw.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

20/07/2022 · It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance. 1 Check whether the tooth peak to tooth valley is match with each other. 2 Regularly check whether the bolts and nuts have been tightened so you must ensure that

Learn MoreJaw Crusher Working Principle - Gravel Mill

Jaw crusher is widely used in industrial and mining enterprises , this is because the aircraft structure is relatively simple , and has a large range of models . Inquiry. Structure of jaw crusher mainly include frame, eccentric shaft, big pulley, flywheel, moving jaw, side guard plate, toggle plate, toggle plate back seat

Learn Morejaw crusher eccentric shaft | machine bearing bush mill

Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square.

Learn MoreT/CWP BOLT SET | jaw crusher eccentric shaft design

PF impact crusher read more It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with a feed particle size not exceeding 500mm and a compressive strength not exceeding 350MPa. , Energy, cement, chemical, construction and other industries

Learn Morejaw crusher eccentric shaft fintec jaw crusher upper head

The rugged design provides the Reliability, quality, capacity, and ease of use you can expect with products from Hewitt Robins and the Jaw crushers are designed to help you be more profitable. Jaw crusher eccentric shaft is constructed with large dimensions of alloy steel with anti-friction bearings and is housed in pitman and dust proof

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

Figure 8.1 shows two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw. A double toggle crusher has, basically, two shafts and two toggle plates.

Learn More

Leave a comment