crusher material handling

Improving jaw crusher safety | Dry Bulk

6/5 · Rock enters the jaw crusher from the top of the machine and gets compressed between two surfaces — the fixed and moveable jaw. The rock will continue to be crushed until it is small enough to fall through the opening. Ensuring that the size of raw material is appropriately matched to the jaw opening, can alleviate blockage incidents.

Learn Morecrusher material handling | HP400 COUPLING HOUSING TH3-127A

Our material handling products cover many applications and are designed for efficiency and high-capacity material transferring, moving and mixing. Our innovative line of material handling solutions includes radial and telescoping conveyors, truck unloaders, hopper feeders, mobile conveyors, pugmills and stationary conveying systems.

Learn MoreMs Jaikar Industry Private Limited, Amritsar - Manufacturer of Magnet

All our material handling equipment, crusher plant and vibrating screens are reckoned for their salient features which includes following: Easy To Use & Setup Durable Longer life Corrosion Resistance Dust proof Low power consumption Low maintenance

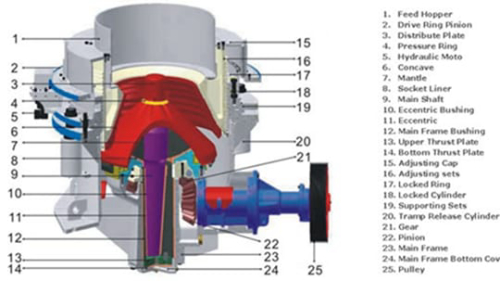

Learn MoreWhat Type of Crusher Is Best for Primary Crushing?

Primary crushers reduce large run-of-mine material, such as rocks and ore lumps, into smaller sizes for further processing downstream,

Learn MoreTypes of Crushing Equipment - Jaw, Cone & Impact

A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size.

Learn Morecrusher material handling

crusher material handling Material Handling. Our material handling products cover many applications and are designed for efficiency and high-capacity material transferring, moving and mixing. Our innovative line of material handling solutions includes radial and telescoping conveyors, truck unloaders, hopper feeders, mobile conveyors, pugmills

Learn MoreEverything You Need to Know About Rock Crushers

As foundational material handling equipment in all plants, crushers need to It is common to use multiple crusher types within a project and set them up

Learn MoreCrushing and conveying - ABB

Electrical equipment and automating systems in open-pit mining and material handling, with more than 700 kilometers of conveyors and several crushers

Learn MoreMaterial Handling Solutions for Mining - Rockwell Automation

Material handling is critical to mining operations. Responsible for movement, storage and blending of the materials, they connect the mine to the market.

Learn MoreAutomated Material Handling Systems (AMHS) Engineering Technician Job

Intel's Technology Development Analytics and Technology Automation (TD ATA) Automated Material Handling Systems (AMHS) group is looking for a highly driven and disciplined individual to join our team as an Engineering Technician supporting AMHS product engineering at Intel's D1 Factory in Hillsboro, Oregon. This will give you the opportunity to

Learn Morecrusher material handling | crusher spare copper-alloy casting to suit

Ash And Material Handling. Dec 17, · Biomass - Ash & Fuel Handling. When it comes to material handling it's important to choose the right tool for the job. Some jobs may need different types of pneumatic ash or mechanical ash conveying systems. All projects are different. A typical ash handling job might explore vacuum ash collecting.

Learn More

Leave a comment