roll crusher design

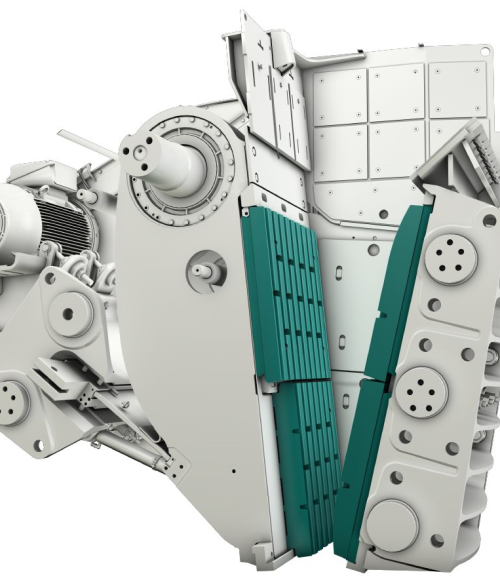

2PG SERIES DOUBLE ROLLER CRUSHER

Advanced Design, High Performance Roller Crusher The Fields Of Application The Feed Materials Roller crushers are used mainly for crushing easily fractured materials such as soft limestone, chalk, and clay to between 1/3 and 1/5 of its original size Double roll crushers are used for both, primary and secondary crushing.

Learn MoreRoll Crusher Design Calculations - S. FABRICATORS

Roll Crusher Detailed Design Sobyin Roll Crushers. Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar. Roll crusher detailed design 9938. detailed calculation of capacity and power of a roll crusher.

Learn MoreRoll Crushers - Top 2022 Models - 911 Metallurgist

It is generally considered that Roll Crushers are specially adapted for intermediate crushing, taking a product from rock- breakers with a maximum diameter of

Learn MoreRoll Crushers - ScienceDirect

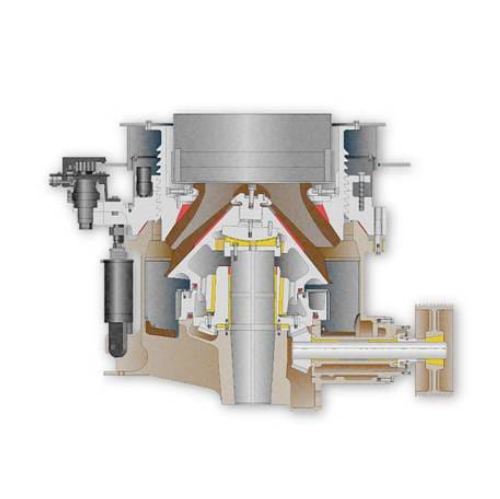

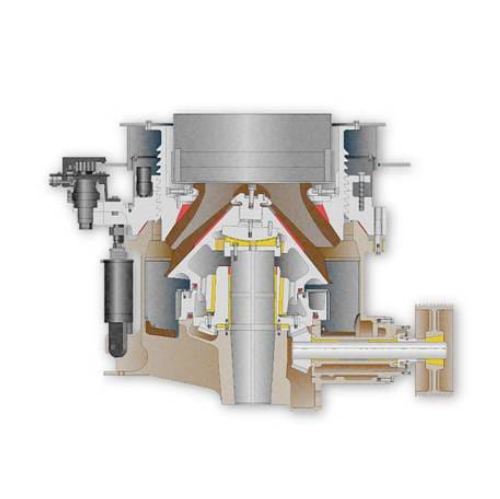

Jan 01, · Two types of roll crushers are generally designed. In the first type, both rolls are rigidly fixed to a frame with provision for adjusting the lateral position of one of the rolls to control the gap between them. Once set these rolls are locked into place. One roll is attached to the driving mechanism while the other rotates by friction.

Learn MoreToothed Roll Crusher Design - Facty Mining Machinery

Design Fabrication and Testing of a Double Roll Crusher. Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work. The throughput capacity of the machine was 1.43tonneshour. The theoretical efficiency of the double roll crusher when crushing limestone was 60 while

Learn MoreTERTIARY ROLL CRUSHER DEVELOPMENT

This report evaluates roll crushers that are proposed for In this design, the crushing roll [8-in. diam (20.3 cm) x 8-in. width.

Learn MoreCrushers - an overview | ScienceDirect Topics

A design for a hammer crusher (Figure 2.6) allows essentially a decrease of the elevated pressure of air in the crusher discharging unit [5]. The A-zone beneath the screen is communicated through the hollow ribs and openings in the body side walls with the B-zone around the shaft close to the inside surface of body side walls. Roll crushers

Learn MoreRoll Crusher With stable Performance | Fote Machinery

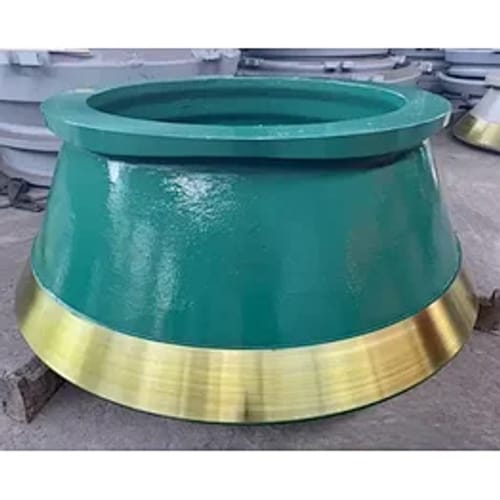

Roll crusher, as one of the most economical and practical crushers, is designed to handle the first and second crushing of friable minerals and stones such as coal, clay, coal gangue, limestone, slag, cement clinkers, and shale, etc.

Learn MoreRoll Crusher Manufacturer & Design

Roll Crushers are simple in design and construction, long-lasting, economical, and versatile across many applications and industries. A combination of impact,

Learn MoreDouble Roller Crusher, Double Roll Crusher Design - PSM

Double Roller Crusher, Double Roll Crusher Design PSM - Tencan Products Made In China, China Manufacturer. Double Roller Crusher Features : The roll

Learn MoreRoll Crusher - an overview | ScienceDirect Topics

Roll crushers apply shear or compression to the material that is going to be reduced in size. This action occurs between two hardened surfaces. The speed and diameter of the rolls, the

Learn More

Leave a comment