pan feeder design

Vibrating Pan Feeders | Deister Machine Company, Inc

Dimensions: Widths: 30" to 96"; Lengths: 6' to 30'". Vibrating pan feeder are used to control the feed of materials into crushers, grizzlys, and onto belts. The feeders can be horizontal or inclined up to 15 degrees for increased capacity. A wide range of liner materials and thicknesses are available. Download product sheet.

Learn MoreHow Important is Feeder Design?

Volumetric screws, belts, rotary valves, louvered, and pan feeders; Gravimetric belts, loss-in-weight, and gain-in-weight feeders; Special

Learn MorePan / Grizzly Feeder

Custom designed & built; Designed for maximum efficiency & output; Heavy duty unbalanced vibro motors; Adjustable amplitude of vibration; Heavy duty,

Learn MoreVibratory Feeder: What Is It? How Does It Work? Types Of - IQS Directory

The general design of a vibratory feeder consists of a drive unit that generates the vibratory action and a deep channel, or trough, that contains the bulk material. The drive unit causes vibrations with both horizontal and vertical force components.

Learn MoreRoxell is expanding the range of MiniMax™ feeder pans

8/27 · For 35 years the MiniMax feeder pan has set the standard for optimal feed intake for broilers. This is due to the patented design: a stepped bottom pan with a special anti-waste edge. Both features improve the chickens’ feed intake and prevent spillage because feed cannot fall over the edge of the pan.

Learn MoreTrio® EF Series Pan Feeders | Weir Group

Honey-comb style steel pan reinforcement. Overhead suspended and pedestal floor mount models available. Heavy and continuous duty design. Ideal for high performance operations. Available in a wide variety of widths and lengths. Can be mounted from horizontal to 10 degree decline. Applications,

Learn MoreFeeder or Conveyor- Which is It? - Jenike & Johanson

Often times, the terms feeder and conveyor are used interchangeably without much thought given to their function and design requirements. A feeder is the means by which the rate of material from a bin ¹ or hopper ² is controlled. When a feeder stops, material flow should stop as well. When a feeder is turned on, there should be a close

Learn MorePan Feeder Flights - Tri Star Design & Manufacturing, Inc

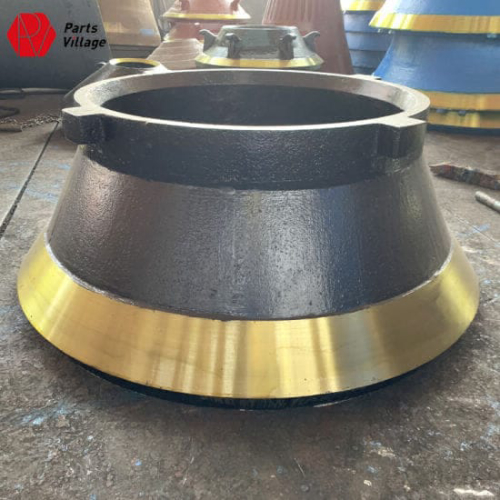

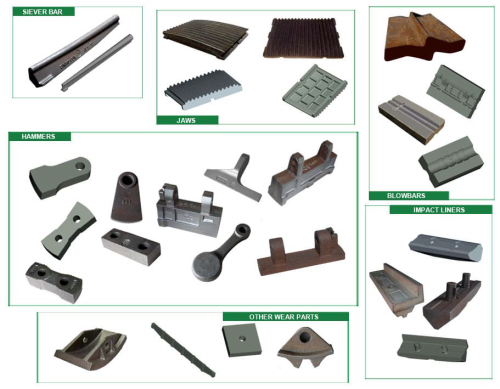

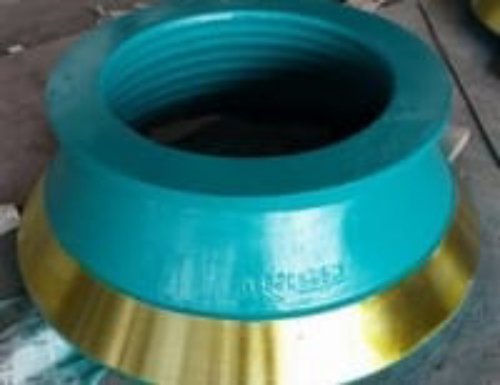

Our custom designed pan feeder flights will replace OEM designs for extended life. Additional information. Use: Conveyor Maintenance. Price Range: Low Budget Estimate, High Budget Estimate. Related products. Head Rotator Cone Crusher $ 55,600 - $ 69,500. Add to Quote. Quick View. Spider Nut $ 2,800 - $ 3,700. Add to Quote.

Learn MorePan Feeders - Astec

Astec pan feeders are mechanically driven with a heavy-duty formed deck and are designed to easily replace competitive models. These feeders feature support springs with guards, bolt-in replaceable liners, re-greaseable bearings and exposed exciters for ease-of-access.

Learn MoreVibrating Feeder Design - Stockpile & Reclaim | General

In most cases, the vibratory feeder pan eliminates the requirements for rack and pinion gates and other shut-off devices above feeders since the feeder pan functions as a shut-off plate. The

Learn MoreLow Sided Pan Feeders - Vibramech

Vibramech low sided pan feeders form part of our brute force vibrating feeder range. With installation angles of 0° (horizontal) to 15°, they are custom-designed for heavy-duty environments. The vibrator motors can be positioned below the pan feeder or side-mounted for compact applications. They provide even, controllable material flow to

Learn More

Leave a comment