nip angle in jaw crusher

Crushing - ASTEC Australia Pty Ltd

Excellent nip angle, Fabricated main frame and swing jaw, Reversible jaw dies Osborn's Laboratory Single Toggle Jaw crushers are designed to reduce

Learn Morestandard crusher parts | nip angle in jaw crusher

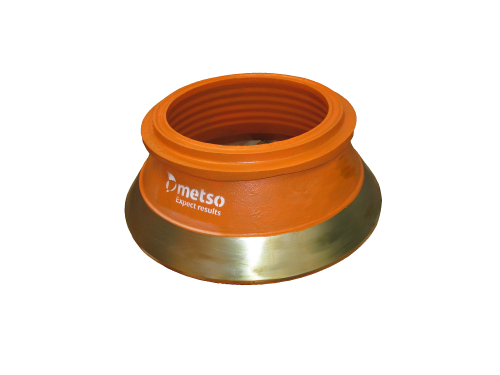

7 ft (2 m) Standard Heavy Duty Cone Crusher Manufacturer: - Secondary crusher - Well maintained from closed mine - Weight: 149,000 lbs - Feed size: 10 - 18 inches (253 - 460 mm) - Production: 380 - 1360 metric tons/hour (418 to 1500 standard tons/hour) - Closed side set

Learn MoreJaw crusher nip angle design choices - 652 Words - NerdySeal

We originally used the concept should be the name of Nine Nine corner angle, Jaw crusher is used to describe the geometry, the importance of nip angle

Learn MoreMEKA Jaw Crushers - Berkshire Engineering Supplies

Large rocks which enter the crusher fall straight into the active region of the crushing chamber. An optimized nip angle ensures the material moves smoothly

Learn MoreFree Essay: Jaw crusher nip angle design choices - 439 Words | Studymode

The concept of work state nip angle jaw crusher to improve the performance of the work provides a new way of thinking. 3 , the impact of : 1 , excessive pressure caused by mineral slip angle , the loading effect is reduced , affecting the broken material . 2, the pressure caused by the slip angle is too large exacerbated jaw plate wear.

Learn Morenip angle in jaw crusher

Up to10%cash back Jaw Crushers: Calculation Methods and Operation Principles. A Review [in Russ. Toggle navigation. Home; About Us; Products; Cases; Solutions; nip angle in jaw crusher 2020-09-18T20:09:45+00:00 Who we are > Products > Cases > Solutions > Contact Us > Solutions. Copper ore beneficiation plant;

Learn MoreA REVIEW - African Journals Online

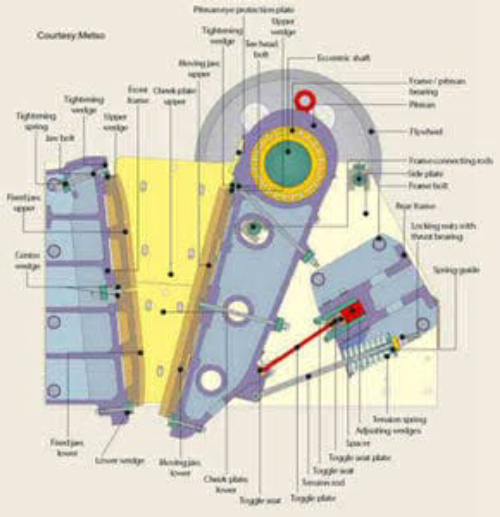

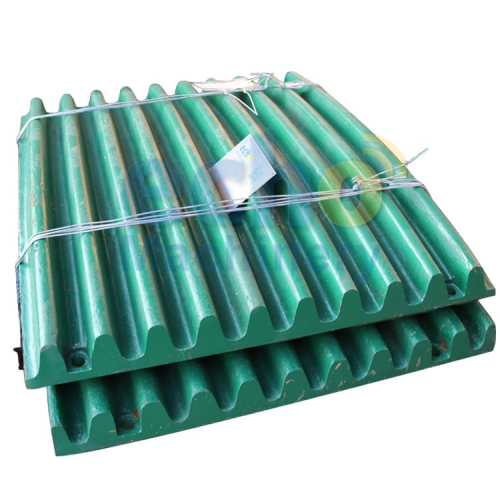

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A Figure 3: Angle of nip in a jaw crusher. 2.3 Crusher Jaw Plates.

Learn MorePEV Series Jaw Crusher - AF Minerals Equipment

The nip angle is the angle between the fixed and movable jaw dies. Too large of a nip angle reduces the capacity and increases the wear as the feed material

Learn MoreNip Angle Jaw Crusher

The correct nip angle between the movable and fixed jaw dies ensures good bite and material flow down even with slippery feed material it also reduces we the jaw dies reducing operating costs with a good grip the jaw crusher can crush rocks efficiently through the entirety of the cavity and the nip angle can be further improved with an

Learn MoreSECONDARY JAW CRUSHER DEVELOPMENT

Moreover, in the case of a fine-reduction jaw crusher, the nip angle becomes increasingly smaller as the particle approaches the discharge

Learn MoreEngineered for the toughest feed materials ® C

The correct nip angle between the movable and fixed jaw dies ensures good bite and material flow down, even with slippery feed material. It also reduces we the jaw dies, reducing operating costs. With a good grip, the jaw crusher can crush rocks efficiently through the entirety of the cavity, and the nip angle can be further improved with

Learn More

Leave a comment