jaw crusher parts pdf

Industrial Solutions Jaw crushers - ThyssenKrupp

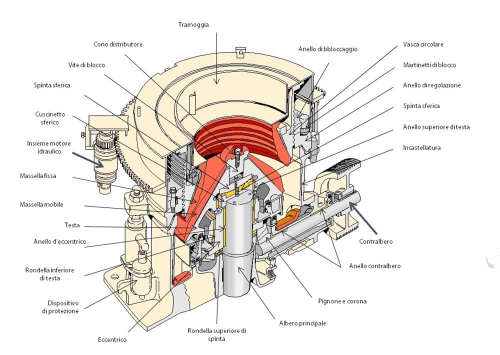

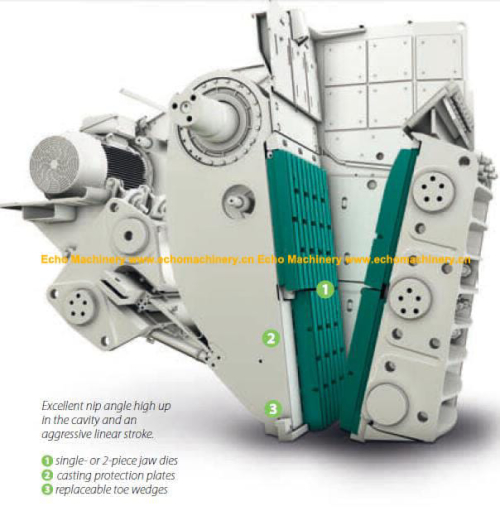

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con - trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and

Learn MoreTRIO CT SERIES JAW CRUSHERS

machine and provides increased wear parts life. TRIO's steep nip angle provides a more aggressive bite at the jaw crusher opening. The opmized rotang.

Learn MoreJaw Crusher Maintenance And Spare Part Manual

Download Terminator Jaw Crusher Manual in PDF format for free. and spare parts on termination equipment should be directed to: jaw crusher repair and overhaul. Cone Crusher Spare Parts Datasheets, Manuals, Linecards, Case

Learn MorePDF Industrial Solutions Jaw crushers - ThyssenKruppPDF

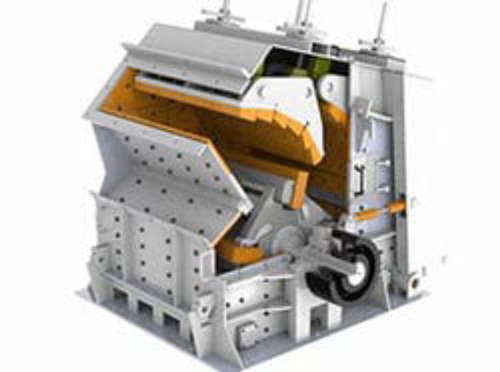

crusher frame and swing jaw made of high-grade steel or special cast steel that has been subjected to a stress- relieving heat treatment in order to pre - vent residual stresses from the welding or casting process • front and back wall reinforced • additional outer reinforcing ribs to coincide with the lines of force • axles precisely

Learn MoreJaw Crushers - Inter Mineral

The jaw crusher is a single toggle jaw crusher, character-ized by attention to detail, in both design and manufacture. We have incorporated the best of the old and applied the benefits of the latest technology. The frame consists of two side plates of rolled steel, plus hollow castings at front frame end and moving jaw which give a high

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

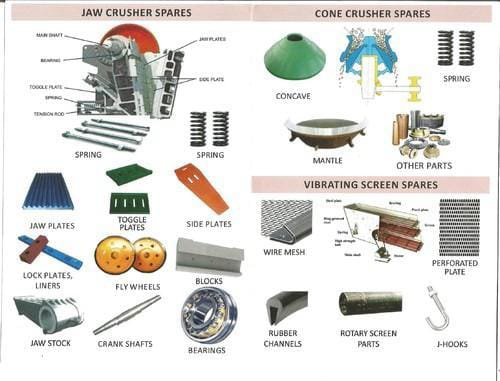

Although the main crushing process is complemented by jaw plates, the crucial parts that give a motion to the moveable jaw plate are toggle plate, pitman bearing and flywheel. The pitman drives the moveable jaw dies to push stone material towards stationary jaws, which would create strong pressing forces to both jaw dies.

Learn MoreC series jaw crushers Wear parts application guide

In crushers like C105 and C3055, the jaw die design on the ends is different. The lock-ing wedges on these crushers are located behind the jaw dies rather than at the top of the jaw die. Jaw dies can be allowed to wear until the thickness is 60 to 65 mm thick, or the teeth are worn flat. On other crushers the ends of the jaw dies are much thinner.

Learn MoreMP1000 VALVE COUNTER BALANCE CARTRIDGE VALVE, | jaw crusher copper

PDF Counterbalance Valve Technical Information Series CB101 • Low leakage poppet-type check valve for reliable load holding • All external parts have yellow zinc dichromate finish. • Parker cartridge design for ease of installation and maintenance • Compact size for reduced space requirements (2) (1) (3) Cylinder (1) Pilot (3) Valve (2

Learn MoreCrushing - KPI-JCI

Pioneer Jaw The Pioneer Series from Kolberg-Pioneer, Inc. represents the very latest in jaw crusher technology. Engineered to be the highest capacity jaw crusher on the market, the Pioneer Jaw Crusher will deliver up to 25% more tons per hour than other comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower

Learn Morejaw crusher spare parts pdf | mill sleeves suppliers united states

jaw crusher spare parts pdf. Industrial Solutions Jaw crushers. Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a double-toggle system, which is con - trolled by a pitman that moves up and down under the influence of an

Learn MoreComputer Aided Design of Jaw crusher

1.2 Different Types of Jaw Crusher According to the amplitude of motion of the moving face; Jaw crusher are classified as follows. a) Blake Type Jaw Crusher Blake type jaw crusher, primary

Learn More

Leave a comment