jaw crusher casting

JAW CRUSHER SERIES - Mining and

SELECTION OF JAW PLATES offers seven teeth patterns and up to three alloy selections (M1, M2, M8) to suit the different types of quarrying and mining applications. Our patterns include Wide Teeth (WT), Wide Wave

Learn Morejaw crusher casting parts manufacturers & suppliers

jaw crusher casting parts manufacturer/supplier, China jaw crusher casting parts manufacturer & factory list, find qualified Chinese jaw crusher casting parts manufacturers, suppliers,

Learn Morehigh manganese steel casting jaw crusher parts jaw plate

high manganese steel casting jaw crusher parts jaw plate wear-resisting degree is higher than traditional one. 2.Using cold processing hardening technology,

Learn MoreChina Jaw Crusher Suppliers & Manufacturers

Casting Frame Jaw Crusher features a deep, symmetrical crushing chamber, easy settings adjustment, a large feed opening for its size, and an ideal nip angle that offers smooth material

Learn MoreJaw Crusher Assembly - sm metal solutions

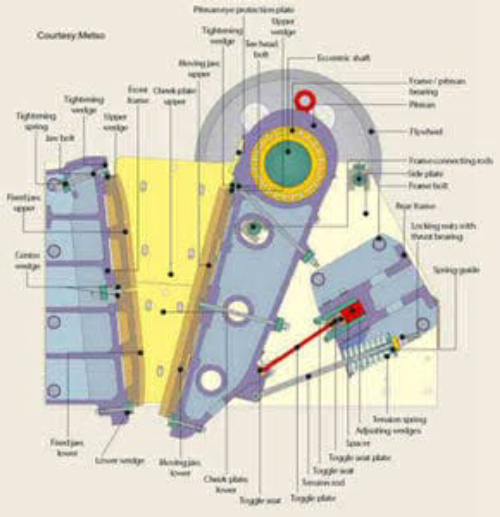

Jaw Crusher Assembly. Components. 1. Flywheel and pulley. 2. Wedge. 3. Pitman. 3. Toggle plate. 5. Toggle Seat. 6. Bolt on lip / Support bar. 7. Cheek plate

Learn MoreNews - Jaw Crusher Liner Casting Types

We use resin sand casting to cast jaw crusher liner. Casting Process Check the drawings and make a 3D model. Make a wood or steel pattern. In sand casting, the mold is made of wood or other metal materials.

Learn Morejaw crusher study casting material new techniques

Die Casting Guide Comments Off on Jaw Crusher's Movable Jaw Casting, Moving Jaw, Jaw Teeth. Product Detail Basic Info Type:Clay Dry Sand casting Method:pressure Crystallization Sand Core Type:Clay Sand Core Application:Machinery Parts Machining:Machining Center Material:Steel Surface .

Learn MoreJaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn Morejaw crusher casting part plant | Portable diesel engine jaw crusher line

jaw crusher casting part plant. Jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc. The pressure resistance strength is under 200Mpa, that is, suitable for primary crush.

Learn MoreSUN ALLOYS - Crusher Parts Manufacturer

INTRODUCTION. We Take This Opportunity to introduce ourselves as the leading manufacturer of Jaw-Plates, Cone-mantle, Rollers, and all other Crusher parts, equivalant to national and international standards. We are a part of the crushing industry since 2010. We started with our 1st unit (Sun Alloys) with a casting capacity of 50 tons.

Learn MoreNews - Jaw Crusher Liner Casting Types

Jaw Crusher Liner Casting Types H&G Machinery has 3 kinds of casting types to cast jaw crusher liner. Sand Casting casting type, V method casting type, and Lose Foam Casting

Learn More

Leave a comment