gyratory crusher manual

Superior™ MKIII 60-89 primary gyratory crusher - Outotec

Superior™ MKIII 60-89 primary gyratory crusher provides increased throughput coming from increased speed and installed power that brings overall benefits to your primary crushing circuit. High throughput Reduced downtime Fast wear parts exchange Increased safety

Learn MoreCrushing and Screening Handbook - AusIMM

the crusher and scalp out fi nes. Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers – capacities available to suit all

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h Cyclo-palloid spiral bevel gear Higher-capacity drive motors if required Rugged design Direct feed possible High throughput rate Optimum degree of comminution Stroke can be changed by adjusting the eccentricity

Learn MoreSUPERIOR® gyratory crushers

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak

Learn MoreGyratory Crushers TC, NT and TS model crushers

performed an ’s solution to a unique Engineering Study of the existing crushing application in Canada was a Station and Foundation and custom designed 72”x 89” Gyratory determined that this customer was Crusher. In addition to this crusher, presented with the unique multiple dual pinion drive crushers opportunity of being

Learn MorePDF Instruction Manual for Gyratory Crusher PXZ-1500IIPDF

Instruction Manual for PXZ-1500II Gyratory Crusher Foreword The instruction manual aims at providing technical guidance for beginners and a technical reference for the experienced operating personnel. Carefully read this manual and keep for future reference.

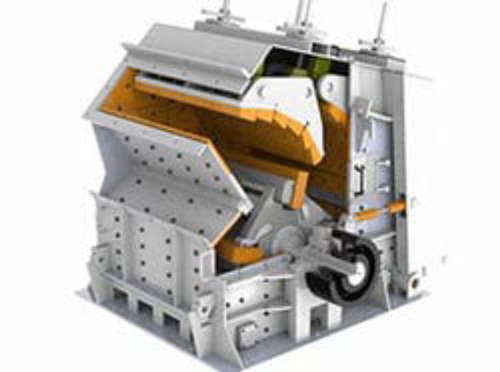

Learn MoreHSC 550: MANUAL JAW CRUSHER - ProLab Systems

HSC 550: MANUAL JAW CRUSHER. The solution for manual crushing and pre-crushing of hard and brittle materials- Your choice for superior quality and cost

Learn MorePDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

be accepted into the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side

Learn MoreExpect results - Metallurgist & Mineral Processing Engineer

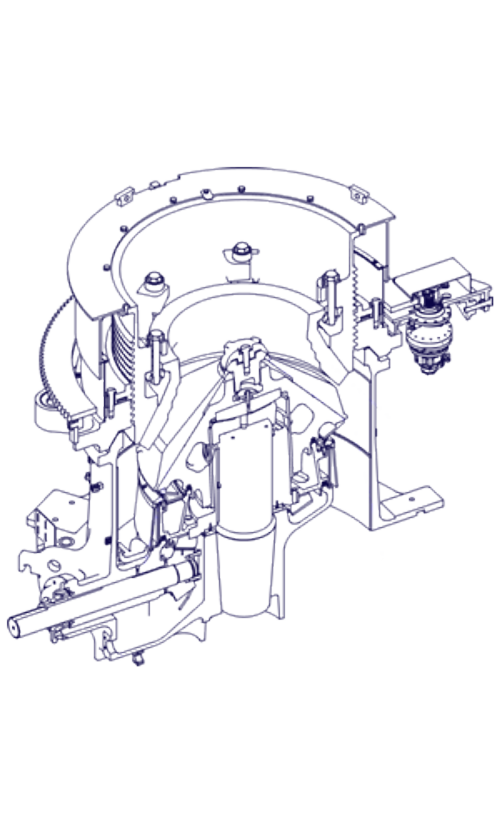

The SUPERIOR® gyratory crusher is a compressive style crusher for primary-stage applications. Its steep crushing chamber and long crushing surfaces provide exceptionally high capacity and long liner life. A gyratory crusher consists of a concave sur-face and a conical head; both surfaces are typically lined with manganese steel. The top

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

Unlike gyratory crushers, the main lubrication used in jaw crushers is grease instead of oil. When using grease, there may be several different ways to inject it into the necessary lubrication points. It can be operated manually with a grease gun, an oiler or metering pump. Video of automatic lubrication system of a jaw crusher

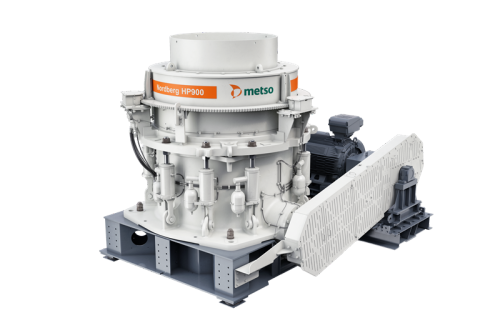

Learn Morehp cone crusher instruction manual

Cone crushers hp series cone crushers cone crusher manual pdf lubrication plant from cone crusher pdf ore crusher grinding mill equipment crusher plantcone

Learn More

Leave a comment