grinding mill liners

Grinding Mill Liners- An Overview

Grinding Mill Liners- An Overview · Solid liners · These are single units with integral lifters and fewer pieces but the downside is a higher

Learn MoreCutting-edge Mill Liners

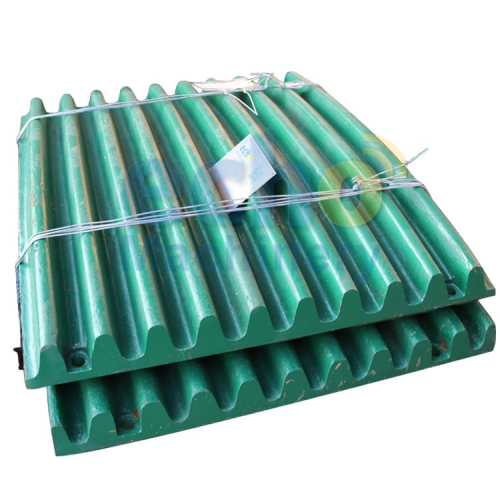

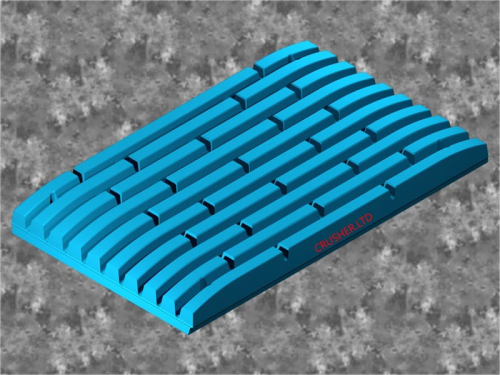

Mill liners fill a basic role: to protect your mills from the intense wear and tear that comes from grinding down hard, raw materials.

Learn MoreGrinding Mill Liners | Products & Suppliers | Engineering360

Liners protect the inside of trunnions from the abrasive action of the material slurry. Worn liners can lead to erosion of the trunnions, mill head, and “fit” area. Unless the erosion is stopped, Form: Loose Liner / Pre-fabricated. Industry & Application:

Learn MoreMill Liner Solutions - Bradken

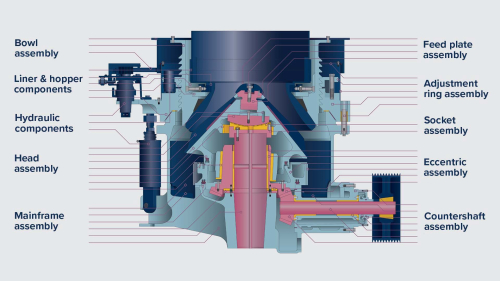

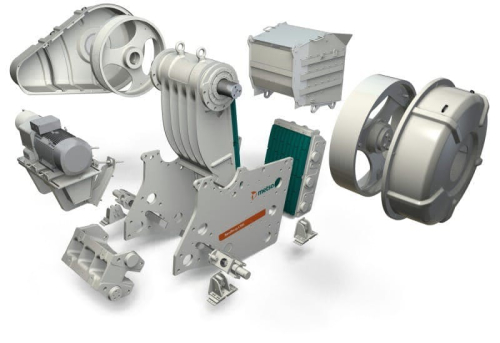

Grinding Mill Solutions Bradken is a leader in the design, manufacture and supply of mill liners for primary and secondary applications in the global mineral processing and quarrying industries. Mill Liner Solutions Bradken is a leading supplier of high quality Mill Liner Systems to suit AG/SAG, Ball and Rod Mills.

Learn MoreBetter Surface Quality With Dia3.8m Steel Cement Mill Liners DF067 For

Mill Liners for sale, Quality Better Surface Quality With Dia3.8m Steel Cement Mill Liners DF067 For Grinding Cement on sale of Zhengzhou Qianyue Mill Liners Co., Ltd. from China.

Learn MoreQuality Ball Mill Liners & Mill Liners Manufacturer

Wuxi Orient Anti-wear Co., Ltd. We are a specialized manufacturer of wear and heat resistant castings. Our main products are Mill Liners for Ball Mills,SAG Mills,AG Mills,Crusher Wear Parts and Grinding Media. 1. The Production 1T,1.5T,3T,5T,12T,15T Induction Electrical Furnace Heat Treatment Electrical Furnace Process.

Learn MoreCeramic Liner Ball Mill Machine Price Ball Grinding Mill Small

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn MoreSelection and Design of Ball Mill Liners

According to different grinding requirements, ball mill liners are roughly divided into 9 types, which are wedge-shaped, corrugated, flat-convex

Learn MoreFive tips on mill liners to improve grinding profitability 2/2

4. Optimized grinding mill liner design. A mill lining should be optimized by design in order to minimize problems, utilize the mill's capacity

Learn MoreRubber - Growth Asia

That is why we utilize the latest design and simulation software to ensure your Mill Liner System will provide optimal grinding performance at the lowest

Learn MoreMill Lining - Tega Industries

Grinding is mostly wet; Ore is ground by making it slurry with water. Grinding Mill Lining. In a mineral dressing plant, the grinding mill body is

Learn More

Leave a comment