gyratory crusher lube system

CG850 Primary Gyratory Crusher With Large Feed Opening

The Tank Instrument Monitoring System (TIMS) provides real-time monitoring of the crusher lubrication system to ensure it functions optimally. Monitoring the Lubrication system, spider bearing grease system and overpressure system, it ensures oils are at the right flow and temperature, and triggers alarms to protect the crusher. Avantages

Learn MoreCG830 Gyratory crusher — SRP - rockprocessing

The Tank Instrument Monitoring System (TIMS) provides real-time monitoring of the crusher lubrication system to ensure it functions optimally.

Learn MorePrimary Gyratory Crushers Failure Lubriion System

Gyratory Crusher Lube System YouTube. 8-2- How a Gyratory Crusher Lube System Works: Certain components in the crusher (pinion shaft and bearings, pinion and eccentric gears, eccentric bushing, and step bearing) require continuous oil lubrication. Auteur: 911 Metallurgy Corp. NEW lubrication system

Learn MoreCommunity-Guided Parks & Recreation System Plan

Welcome to our project page! Please join us in updating our community's vision for Parks & Recreation in Hillsboro. Your input will help build a System Plan that guides parks and recreation development for the next 15 years to serve everyone!. What should Hillsboro's parks look like in 50 years?

Learn MoreFive steps to optimize crusher’s lubrication system - Outotec

7/30 · At minimum, lube system maintenance checks, inspections or servicing must include the following steps: 1. Monitoring of lube oil temperature. A lot can be learned about a cone crusher by simply watching the supply oil temperature and comparing it to the return oil temperature. Return oil temperature should be in the range of 60~140ºF (15~60ºC

Learn MoreIntroduce The Lubrication System of Gyratory Crusher

Pastebin.com is the number one paste tool since 2002. Pastebin is a website where you can store text online for a set period of time. A self-contained lubricating system of gyratory crusher for operatively lubricating the mounting mechanism and the drive train

Learn MoreEngage Hillsboro

Community-Guided Parks & Recreation System Plan. Shape the plan that will serve our growing community for the next 15 years and beyond. Explore & Engage. Year-Round Shelter. Let us know what's important to you as we work with community partners to provide shelter options.

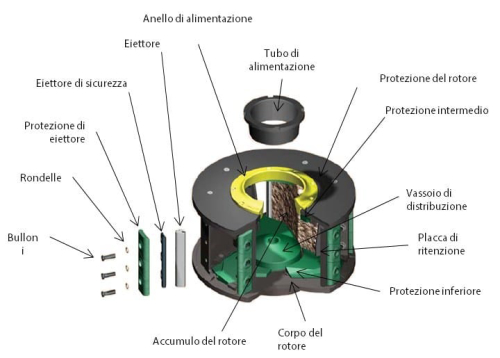

Learn MoreInstruction Manual for Gyratory Crusher PXZ-1500II

1 Section 1 Safe Operation of Equipment 1.1 Introduction The gyratory crusher of CITIC Heavy Machinery company is mainly used in mines, quarries, metallurgy and other fields. During its process of design and manufacturing, we take full account of the influence

Learn MoreGyratory Crushers - SolidsWiki

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone thin oil lubrication system components etc.

Learn Morecrusher lube system flow meter mining

kraft cone crusher lubrication kraft cone crusher s lubrication - Kraft cone crusher lubrication crusher lubriion ore powerplantinstitute oil lubriion for cone crusher as a global leading manufacturer of products and services for the mining industry our company can provide you with advanced mill slide shoe lubrication system oct 08 quarry central lubriion

Learn MoreGrease Lubricating System Used in Different Types of Stone Crusher

Normally, operating an oil-lubricated crusher with contaminated lubricating oil (old, dirty oil) is a common mistake followed by maintenance people. As a thumb rule, operators should use gear lubricants added with extreme pressure additive with a minimum oil viscosity of 22 CST at the bearing operating temperature.

Learn More

Leave a comment