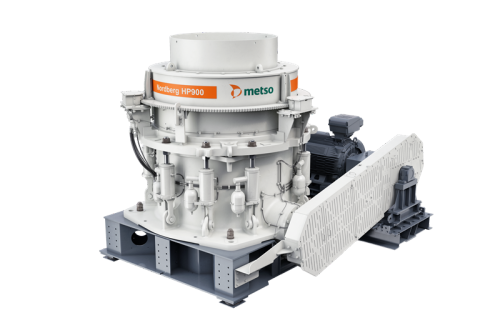

crusher wear liners

Crusher Liners | World-Leading Crusher Liners | CMS Cepcor

Cavity and liner selection CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various metallurgies for impact crushers. Quality assured to Lloyds Register ISO9001:

Learn MoreCSP Impact Crusher wear parts - Cast Steel Products

Engineered for the toughest feed materials CSP Impact Crusher wear parts are designed for processing all hard rock types including rock, sand, gravel, or recycled materials in surface and underground operations. CSP Impact Crusher wear parts include: Blow bars Breaker plates Liner plates Tip sets Distributor plates Wear plates Anvils and shoes

Learn MoreR Crusher Wear Parts Reference Guide

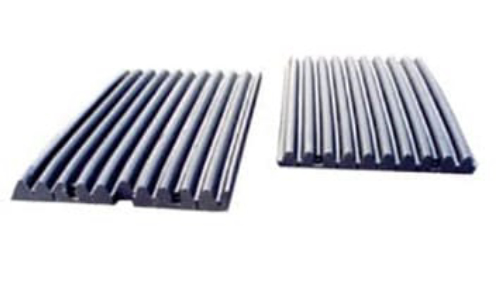

Standard fit on all Jaw & Cone crushers. A good all round liner for all applications. 22% MANGANESE Optional fit for all Jaw & Cone crushers. Work hardens quicker in abrasive applications. 14% MANGANESE This is an option that & available if required although not generally stocked. For use in soft low abrasion applications.

Learn MoreJaw Crusher Liners | Foreman Equipment

OEM Crusher wear parts designed to match original design specifications ensuring the best performance from jaw, cone, and impact crushers. Office - Toll Free: 888-852-9021 | 44109 Yale Road West, Chilliwack, B.C. V2R 3Z9 . Jaw Crusher Liners.

Learn MoreAR Steel Crusher Liners - Crusher Wear Liner Supplies | Ford Steel

Ford Steel offers Wearalloy 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy plate up to 4-inches thick for AR steel crusher liners in impact, jaw, cone and other types of crushers. Wearalloy Superclad available for use as cheek plates too. Our company provides crusher wear liner supplies to a wide range of industries including: Sand & Gravel

Learn MoreTips For Buying Crusher Wear Liners - The Riverenza

When buying crusher wear liners, it's crucial to determine the life of each liner. The life of each liner depends on several factors, including rock parameters, tonnage handled, and design of the crushing chamber. When the wear liners are not used as they should, they will need to be replaced sooner, wasting production time and increasing costs.

Learn MoreProlonging Cone Crusher Liners Working Life - Precision Casting

The chamber is lined with wear components, cone crusher wear parts namely the mantle and concaves. As the stone drops though the choked chamber, squashing is attained when the motion of the mantle causes compressive and abrasive pressures to act upon the stone and also dish liner, creating the rock to damage.

Learn MoreTips For Buying Crusher Wear Liners – The Riverenza

Crusher liners wear differently depending on their feed material gradation and discharge setting. Your replacement wear part provider should conduct a wear study to

Learn MoreCrusher Liner - WALDUN | Crusher Wear Liner | Mining

Crusher Wear Liner WALDUN Crusher liner is in the interior of the crusher and belongs to the consumable equipment. That is, in the work time, the internal parts with the extension of

Learn Morecrusher liners - wear liner - A&S Machinery Co., Ltd

For cone crushers,the wear liners are mantles,bowl liners/concaves and cheek plates.For jaw crushers,the wear liners may contain swing jaw/movable jaws,jaws fixed.For hammer crushers,the wear liners are just swing hammers but for impact crushers,the wear liners will cover the impact bars,blow bars.All those crusher wear parts are compatible

Learn MoreKenco Longer Wearlife Parts | HSI Wall Liners

Features and Benefits: Eliminate premature wear experienced with factory-style manganese liners that do not "work harden". Impregnated to a minimum depth of .25" with crushed Tungsten Carbide for longer wearlife. Wear surface hardness of 90 Rockwell A at time of installation. Less crusher downtime, fewer liner replacements. Available for most

Learn More

Leave a comment