crusher cone liner

GUBT Cone Liner factory and suppliers

Cone Liner At present, GUBT could cover 900+ wear parts for cone crushers including bowl liners and mantles for all the industry's leading brands.GUBT's.

Learn MoreProlonging Cone Crusher Liner Life - Agg-Net

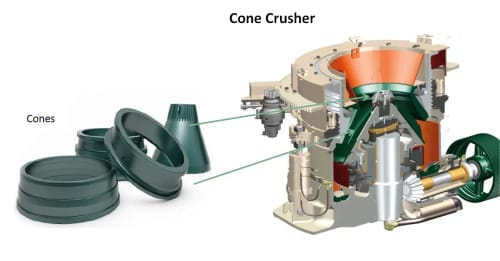

Cone crushers operate by having stone fed into the top of the crusher chamber. The chamber is lined with wear parts, namely the mantle and bowl liners.

Learn MoreBowl Liner & Mantle | Wear Resistant Crusher Parts | GTEK

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: mantle and bowl

Learn MoreCone Crusher Liners: What To Choose And When To Change

Closed-side feed openings are passing 90-100% There are those who examine 80% of the open side too and choose the lower one of two. 40-60% passing the midpoint. Closed-side Setting Closed-side Setting: 0-10%. Matching the entire feed gradation and not just the feed size is essential so you can make use of your chamber to the maximum.

Learn MoreCone Crusher Liners | Manufacturing and service of Gyratory

In order to help your site maximise its operational performance, we design Cone Crusher Liners and wear parts that are tailored specifically with your needs and

Learn MoreHow to Select and When to Change Cone Crusher Liners

Cone crusher liners reduce the volume of the crushing cavity and feed opening of the cone crusher. If the liners wear out, a 10% loss in production is enough to justify changing them. If not, failure to replace the liners will not only cause a loss in production, but can also damage internal crusher components.

Learn MoreCone Crusher Parts - SHANVIM

HIGH MANGANESE STEEL ACTIVE BOWL LINER. The material of SHANVIM concave and mantle: Mn13Cr2, Mn14Cr2, Mn18Cr2, Mn22Cr2, ASTM A128 Gr A & B2 & B3, BS 3100 Gr

Learn MoreCone Crushers | McLanahan

As the crusher operates, the system will track production capacities and calculate the liner wear rate. When the cone liners reach the maximum wear point, it sends a flashing reminder to 'change cone' on the cone setting meter. After the wear parts are changed, simply reset the automated reminder system and continue efficient, reliable crushing.

Learn MoreCone Crusher Liners: What To Choose And When To Change - KeepandShare

Cone Crushers are equipped with crushing chambers. It is the space between the concaves and mantle, which is the moving piece of steel. Concaves and mantles are protected from daily wear by replaceable manganese liners. Selecting a Cone Crusher liner There are numerous liners for both fine and coarse feeds.

Learn MoreCone Crusher Replacement Wear Parts – Columbia Steel Casting

OEM liners are based on average conditions, and few cone crushers work under “average” conditions, which is why we have so many options available. Matching sets for better production Our engineers work to improve production throughout the liner life, and to arrive at even wear ratios between mantle and liner to minimize discard weight.

Learn MoreCrusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Leave a comment