hammer mill machine working principle

The uses and working principle of the vertical hammer mill

12/11 · The uses of vertical hammer mill. Vertical Hammer Mill (We also called metal ball crusher machine, vertical mill, or vertical metal shredder)is used to pulverize materials in the extreme fineness

Learn MoreSingle Stage Hammer Mill Principle And Working

Feb 25, Hammer Mill Operating Principle. Operational Characteristics : The method of operation has a con siderable effect upon the nature of the product. When minimum fines are a requirement, the hammer mill should always he operated in closed circuit with a screen, or screens; the cir culating load should be fairly high; speed should be as low as is consistent with physical structure of

Learn MoreHammer Mill Operating Principle - 911 Metallurgist

The Dixie (Non-Clog) Hammer Mill Crusher differs from all other hammermills in that its breaker plate, instead of being stationary, is a

Learn MoreHammer Mill - Principle, Construction, Working, and Advantages

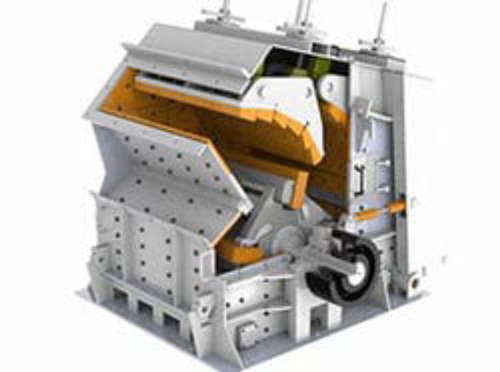

Advantages of Hammer Mill: Hammer mill is easy to install, operate, dismantle and clean up. It occupies less space and can be easily placed in one corner of the manufacturing area. Various grades of material can be handled using screens of different sizes. It is versatile, and speed and screens can rapidly change based on milling requirements.

Learn MoreHammer mills : an engineering overview. What is it ? How

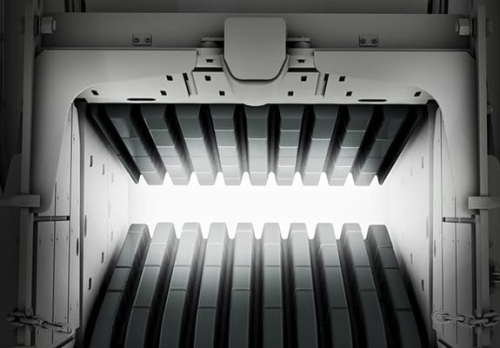

The working principle of a hammer mill is to have a rotor, equipped with hammers (thick plates) rotating at high speed within a casing, that may be equipped with a grid, and that reduces the

Learn MorePDF) Development and Performance Evaluation of Improved

The machine consists of a hopper, a milling chamber with hammers assembly, a pulverising chamber with two abrasive surfaces, a screw feeder,

Learn MoreHammer Mill Working Principle

Water Drop Hammer Mill Grinding and Milling Equipment 5.The rollers can work on both directions with slight vibration. 6.Energy conservation. The electricity consumption is 5.5 kwh, lower than average 6.7 kwh. Hammer Mill Working Principle. Raw material are fed

Learn MoreDESIGN & CONSTRUCTION OF HAMMER MILL MACHINE | Afribary

5). Design calculations and specifications of every component of the machine will be carried out after which the assembly of the components will be done. 6). A standard blue print ie assembly and component drawings will be produced. Based on these drawings, the construction of the machine will be carried out. 7).

Learn Moremill hammer mill working principle

High speed hammer mills (tip speed from 40 to 70 m/s) can allow to reach small particles sizes, below mm A universal mill is a derivation of the hammer mill

Learn Morehammer mill machine supplier & working principle | iranmachin

hammer mill machine supplier, with the production of this machine, help to many industries, to reduce the size of their product. working principle of hammer mill machine is reducing size. & it is so essential for Fertilizer & Animal feed industry.

Learn MoreHammer Mills: Working Principle, Types and Application

Hammer mill is among the oldest, commonly used size reduction machine consisting of a series of hammers (usually four or more) hinged on a focal shaft and encased securely within a rigid

Learn More

Leave a comment