gear hobbing machine setting

The Gear Hob Process - Gear Technology

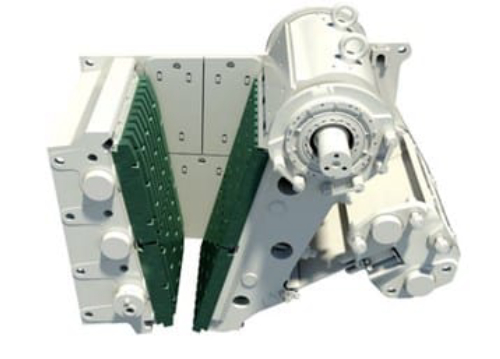

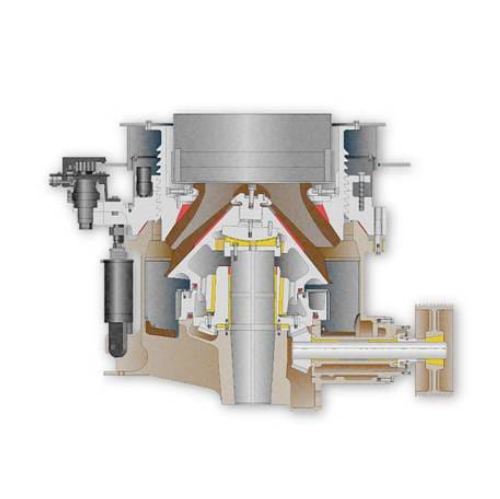

The Gear HobbinglMachine Agear bobbillg machine consistsoffive common elements: • Awork spindle to rotate the work. • A hob spindle to rotate the hob. oA means of rotating the work spindle and hob spindle with a constant of ratio, depending on the number of teeth in the workpieceami the number of threads ill the hob.

Learn MoreMikron gear hob machine - pjn.yukkuri.shop

I've bought a small hob machine which cuts spur gears only. It's a Mikron 112. The machine is complete and working, just needs cleaning and lubricating and a VFD fitted for the motor, I have a full set of change gears and a decent number of cutting hobs.

Learn MoreGear hob machine setting Kerja, Pekerjaan | Freelancer

Cari pekerjaan yang berkaitan dengan Gear hob machine setting atau upah di pasaran bebas terbesar di dunia dengan pekerjaan 21 m +. Ia percuma untuk mendaftar dan bida pada pekerjaan.

Learn MoreA Tooth Flank Crowning Method by Applying A Novel Crossed

In the conventional gear hob process, the longitudinal crowning for tooth angle of the hob cutter and work gear as a fixed machine-tool setting.

Learn MoreGear Hobber Casting Set - martinmodel

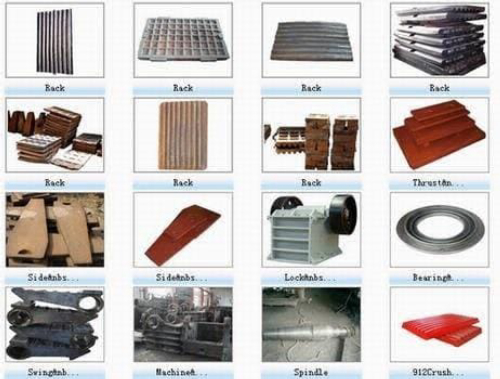

Gear Hobber Casting Set $495.00 Add to Cart The gear hobber is a machine for producing gears by the hob process: a rotating gear blank is fed into a gear hob (in the shape of a worm). The maximum capacity is about 4" in diameter, 20 dp (diametrical pitch), 1.25 module down to 1/10" diameter, 120 dp, 0.2 module.

Learn MoreGear Hob Solutions - CNC Vertical Gear Hob Machines

We at EIFCO have been manufacturing gear hob machines for over 40 years. With a single point agenda of seamlessly increasing productivity while enhancing quality, we ventured into manufacturing NC machines. The astounding success that came with the introduction of NC machines gave us the impetus to develop the CNC Gear Hob Machine.

Learn MoreHob - Wikipedia

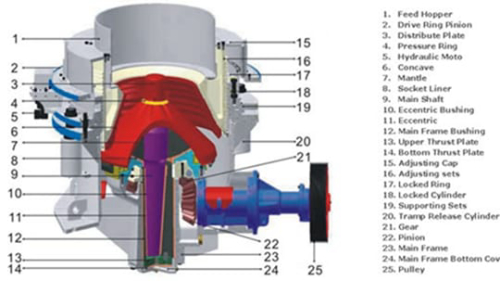

Hob machines are characterized by the largest module or pitch diameter it can generate. For example, a 10 in (250 mm) capacity machine can generate gears with a 10 in pitch diameter and usually a maximum of a 10 in face width. Most hob machines are vertical hobbers, meaning the blank is mounted vertically.

Learn MoreA Guide to Gear Hob - Avon Machining

Oct 27, · Gear hob is a quick and versatile process that is fundamental for gear manufacturing. Gear hob machines utilize a rotating cutting tool, or hob, to generate a

Learn More2.4.18 Gear hob machine - - Impresa Sicura

Machine tool that removes chips of material, used to make external gear teeth. Contact with motion transmission and adjustment equipment.

Learn MoreThe process of Gear Hobbing. ||Engineer's Academy

Mar 13, · Hello Everyone Welcome To Engineer's Academy Topics Covered : In this Video We have done with the Practical Manufacturing of the Gear hob , Please Che

Learn MorePDF) Adjustement aspects of gear hob machines in

On their basis and using a calculation program the pears of change gears necessary for adjusting the threading kinematic chain are determined.

Learn More

Leave a comment