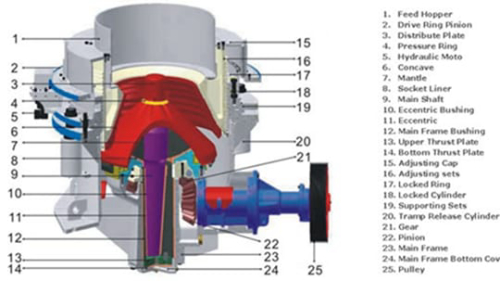

cone crusher assembly

Cone Crusher Assembly - SM Metal Solutions

Cone Crusher Assembly Components 1. Top Shell Casting 2. Retainer / Torch Ring 3. Bottom Shell Casting 4. Pinion 5. Gear 6. Mantle 7. Concave / Bowl Liner 8. Upper Concave Segments

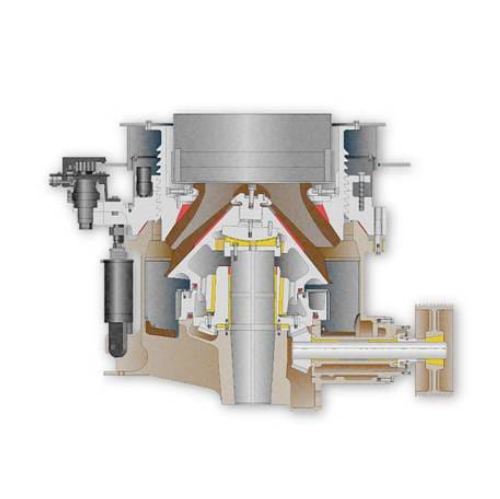

Learn MoreTrio® TC Series Cone Crushers - The Weir Group

The modern hydraulic features of the Trio® TC Series cone crusher allow push button adjustment of the CSS and easy bowl installation and removal.

Learn MoreCone crusher assembly work

Cone crusher assembly work https://www.hotel-restaurant-lepic.fr/

Learn MoreGP Series™ cone crushers - Outotec

Features. ® GP Series™ cone crushers have been developed to crush feed materials into desired end products efficiently, reliably, and economically. Engineered for all rock types, these machines can be utilized as secondary, tertiary, and quaternary crushers in aggregates production plants and in mining operations.

Learn MoreCone Crushers TC1000 & TC1300

lower the upper frame assembly to adjust the crusher setting and to unblock the crushing chamber ACE6 Control System as Standard Mantle Nut Upper Frame Radial Bearings Taper Roller Bearings Basic cone crusher only 10,000 22,040 22,000 48,500 Crusher assembled on live frame with motor, motor pulley, Vee belts and drive guard

Learn Morecone crusher main shaft assembly

Feb 19, · Cone Crusher MAINSHAFT. The mainshaft is of high grade forged steel, annealed for stress relief. It is tapered to gauge for head center fit. The bottom of the shaft is fitted with a polished bronze step bearing. The journal for the spider bearing is formed by a

Learn MoreCONE CRUSHER - CT950 - CONETECH ENGINEERING

CT950 CONE CRUSHER DIMENSIONS. A) 1690 mm / 66.5 in B) 331 mm / 13 in C) 2255 mm / 88.7 in E) 1889 mm / 74.4 in F) 1125 mm / 44.3 in G) At Maximum Setting: 1870 mm / 73.6 in

Learn MoreUS3834633A - Bowl and mantle assembly for cone crushers - Google

Liner assemblies for the bowl and mantel of a gyratory cone crushing machine. Each assembly includes a liner backing plate formed from a material of low abrasion resistance, such as mild steel, and which takes the form of a truncated cone to conform to the associated bowl or mantle. The crushing surface of the liner assembly is defined by a plurality of arcuate segments cast from martensitic

Learn MoreCone Crushers | Crushing Plants | DOVE

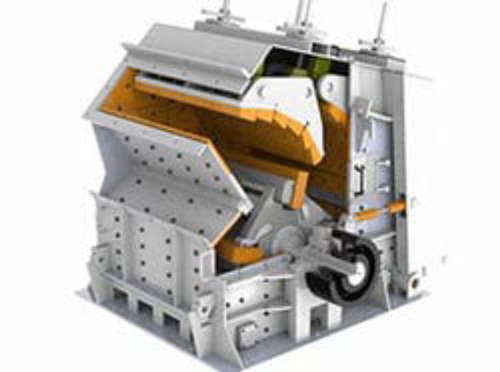

Continuous Lubrication. Cone Crushers are configured with Hydraulic Lifting-Arm, where in the case of power failure, it allows the operator for rapidly rotating and removing the top-shell in order to remove the stuffed material inside the crushing chamber. The hydraulic adjustment unit will also allow easily and rapidly to perform the required setting adjustments, and changeovers of discharge

Learn MoreLocking nut assembly for a cone crusher - Google Patents

A two-piece locking nut assembly for securing a mantle to a head assembly of a cone crusher. The two-piece locking nut assembly includes an inner nut and an

Learn MoreEP3512636A1 - An eccentric assembly for a cone crusher - Google Patents

An eccentric assembly for a crusher is disclosed. The eccentric assembly attaches both an eccentric and a counterweight to an underlying rotatable gear that supplies rotational force to the assembly. The eccentric includes an eccentric barrel and an eccentric flange, and the sides of the eccentric are disproportionately weighted.

Learn More

Leave a comment