crusher jaws

Crusher Jaws - Battle Pet Ability - World of Warcraft

At the end of the round,Jawbone will cause a devastating bite at the enemy pet, dealing 0%. In the Aquatic Battle Pet Abilities category. Always up to date.

Learn MoreJaw Crusher For Sale | Jaw Crusher | Jaw Crusher Manufacturer

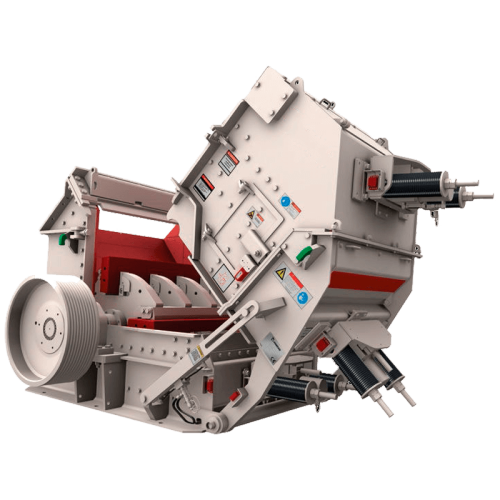

Jaw crusher for sale. Production Capacity: 1-1200 t/h. Feeding Size: 125-1200 mm. Application: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc. . The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa. Widely

Learn MoreHow Does a Jaw Crusher Work - Kemper Equipment

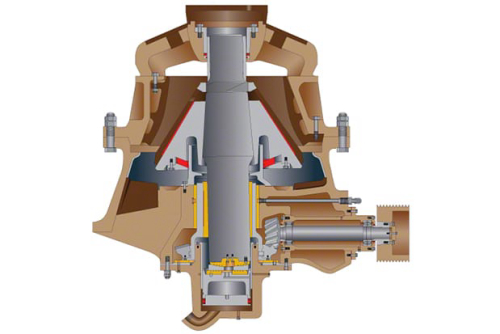

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary

Learn MoreJaw Crushers - Best Models for 2022 - 911 Metallurgist

Jaw Crushers - Best Models for 2022 · 1″ x 2″ Mini Rock Crusher · Small Jaw Crusher 2 1/4″ x 3″ · 2″ x 6″ Rock Crusher · 3″ x 4″ Jaw Crusher · 6″ x 10″ Jaw Crusher.

Learn MoreHow to Select the Right Jaw Crusher - Gilson Company

All jaw crushers operate on the same straightforward principle; two hard-faced heavy plates or jaws crush large particles between them.

Learn MoreJaw Crushers | McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern

Learn MorePE 600X900 Limestone/Coal/Basalt/Granite/ Jaw Crusher for Sale

Jaw Crusher Machine Working Principle. When Jaw crusher working, motor through the pulley drive the eccentric shaft rotation, from the period of hubei near, fixed jaw, and for the material such as extrusion, rolling and run multiple broken, make material from large to small, gradually whereabouts until discharge through the discharge port.

Learn MoreCR 300 Crusher - Jaws Mini Crushers

EFFICIENT OUTPUT The CR300 Crusher's highly abrasive, resistant jaws and unique patent-pending crushing mechanism effortlessly crushes up to 6 tons of concrete an hour. With performance that is comparable to bigger crushers, its compact size makes it a more manageable and less daunting machine to use. TIME AND COST SAVING

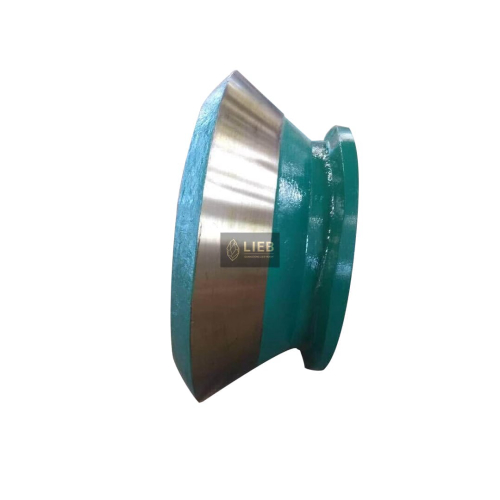

Learn MoreWhat are the Materials of the Jaw Crusher Plates and Which is

What are the jaw materials of the jaw crusher? High manganese steel. High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance.However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to

Learn MoreType of crushers and their difference - JXSC Mining

10/12/ · Jaw crusher is used as primary crusher, it’s reduction ratio is usually 6:1. It uses compressive force to break the material, this mechanical pressure is achieved by the two jaws of the crusher. It is called a jaw crusher because it works the same was a human jaw does-food goes into your mouth and your bottom jaw pushes the food up against

Learn MoreSamscreen's Replacement Jaws for Crusher Machines

If you need a replacement jaw for your crushing machine that can withstand the toughest conditions, then you need Samscreen's Maxwear™ manganese jaws. Our replacement jaws feature Maxwear™ manganese in three grades depending on the crushing conditions encountered - 14 percent, 18-19 percent, and 21-23 percent. Samscreen's replacement jaws offer excellent wear life and fit and go through a rigorous quality control process.

Learn More

Leave a comment